PRODUCTS INFO

Leakless magnetic pumpNon self priming typeHDG-PX/PF[Small model]

-

Hose

-

Flange

-

Thred

-

Thred with union

Pump variations

| Model | Main material | Max temp. |

|---|---|---|

| HDG-PX | GFR-PP | 60℃ |

| HDG-PF | CFR-ETFE | 90℃ |

Features

Leakless

There is no need to worry about leak

due to magnetic drive construction.

Chemical resistance

suitable for transferring the liquid without the slurry.

the liquid incl slurry is prohibited.

Easy maintenance

The Wet-end parts is comprised of a small number of parts

(Front casing/Rear casing/ Impeller/0-ring) .

so replacement of parts and maintenance is easy.

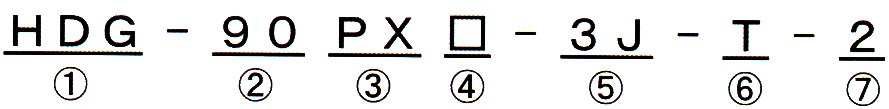

Pump identification

-

(1) Series symbol (HDG)

(2) Motor power (W)

(3) Pump model / main material

PX : GFR -PP

PF : CFR-ETFE -

(4) Pump performance

(NON) : Standard type

Z : High head type

X : Low head type(5) Motor phase

(NON) : Single phase (1Ø)

3J : Three phase (3Ø) -

(6) Casing connection

H : Hose (mm)

T : Thread (Inch)

F : Flange (A)(7) Voltage

1 : 100V

2 : 200V

3 : 380V

4 : 400V

Non self priming typeHDG-PG/TF/TC[Middle-Large model]Self priming typeHDG-NS[Middle model]

-

HDG-PG

HDG-TF -

HDG-TC

-

HDG-NS

Pump variations

| Model | Main material | Max temp. |

|---|---|---|

| HDG-PG | GFR-PP | 70°C |

| HDG-TF | CFR-ETFE | 90°C |

| HDG-TC | CFR-ETFE+FC cover | 90°C |

| [Self priming type] | ||

| HDG-NS | GFR-PP | 70°C |

Features

Leakless

There is no need to worry about leak due to magnetic drive construction.

Chemical resistance

Suitable for transferring the liquid without the slurry.

The liquid incl slurry is prohibited.

Easy maintenance

The Wet-end parts is comprised of a small number of parts (Front casing/Rear casing/ Impeller/0-ring) .

so replacement of parts and maintenance is easy.

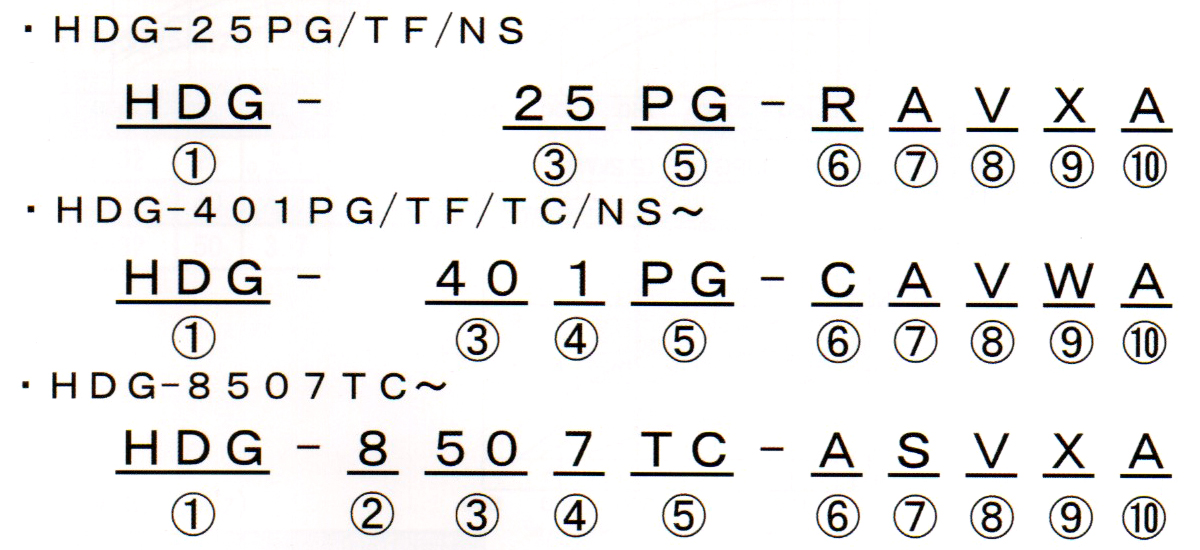

Pump identification

-

(1) Series symbol (HDG)

(2) Bore (Inlet)

8 : 80A (85**TC series only)

(3) Bore (OutIet)

25 : 25A

40 : 40A

50 : 50A

5 : 50A (85**TC series only)(4) Motor power (kW)

0 : 0.4kW

1 : 0.75kW

2 : 1.5kW

3 : 2.2kW

5 : 3.7kW

7 : 5.5kW

10 : 7.5kW

15 : 11kW

20 : 15kW -

(5) Pump model/main material

PG : GFR-PP

TF : CFR-ETFE

TC : CFR-ETFE (+FC cover)

NS : GFR-PP(6) Bearing material

C : Carbon

R : Reinforced PTFE

A : Ceramic

S : SiC(7) Spindle material

A : Ceramic

S : SiC -

(8) 0-ring material

V : FKM

E : EPDM

S : Special(9) Frequency code

X : 50Hz

W : 60Hz(10) lmpeller size code

A : S. G. 1.1 MAX

B : S. G. 1.3 MAX

C : S. G. 1.5 MAX

D : S. G. 1.9 MAX

S : Special

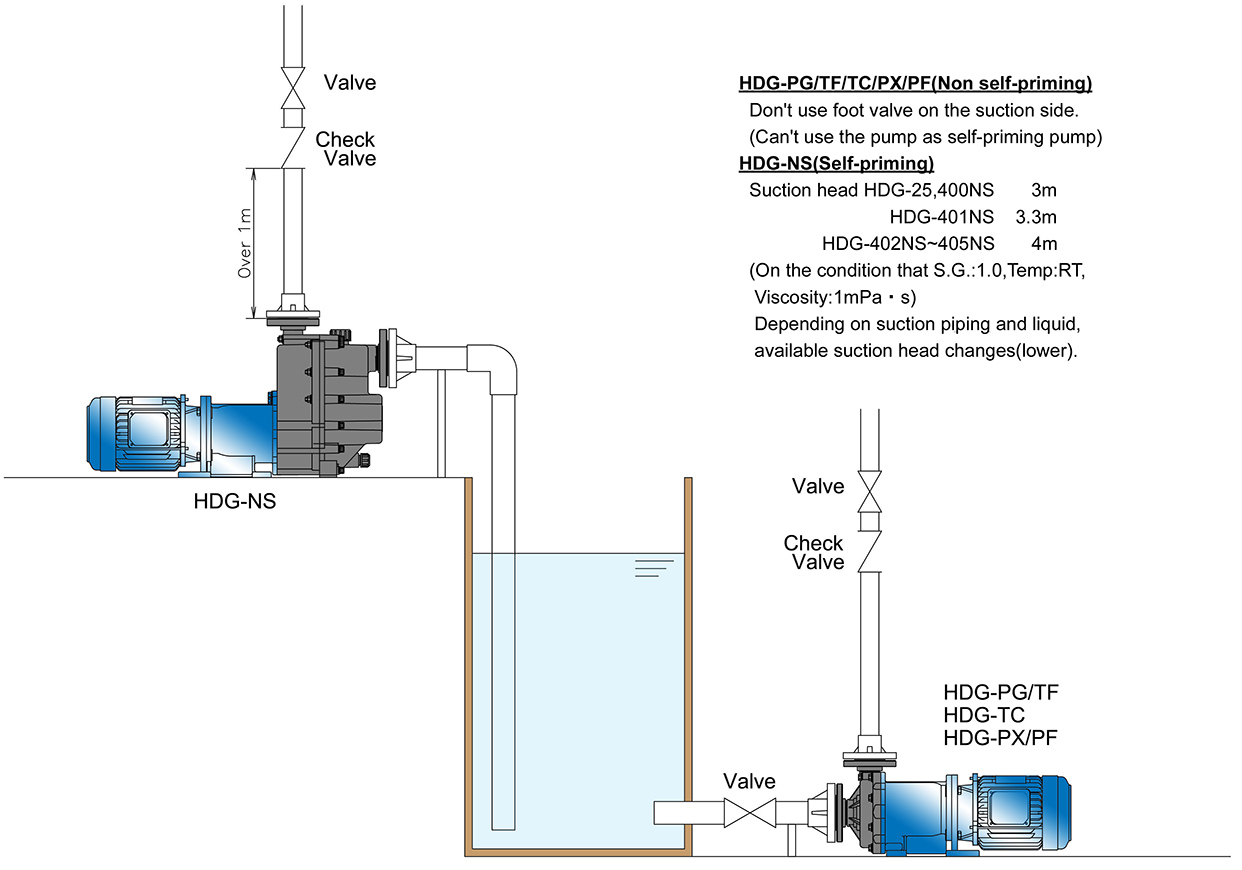

Pump installation example

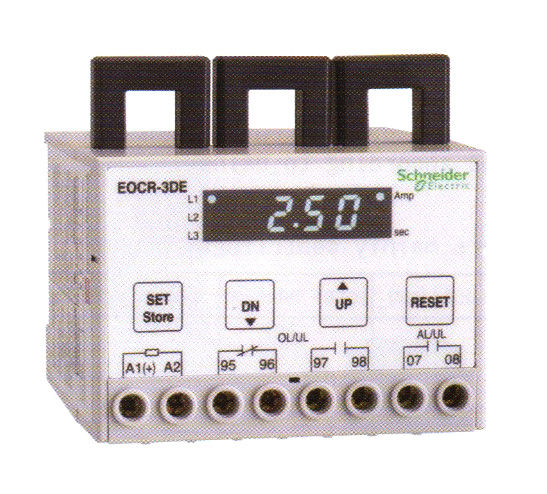

OptionPump protector

[Current detection type]

| Model |

|---|

| EOCR-3DE / Panel Mounting type |

| EOCR-FDE / Flush Mounting type (Display) |

Features

- Compact design

- Protection for over current, under current, phase loss, phase unbalance, phase reversal, stall, locked rotor, ground fault.

- Current range : 0.5A ~ 60A

- Voltage : 100V ~ 240V